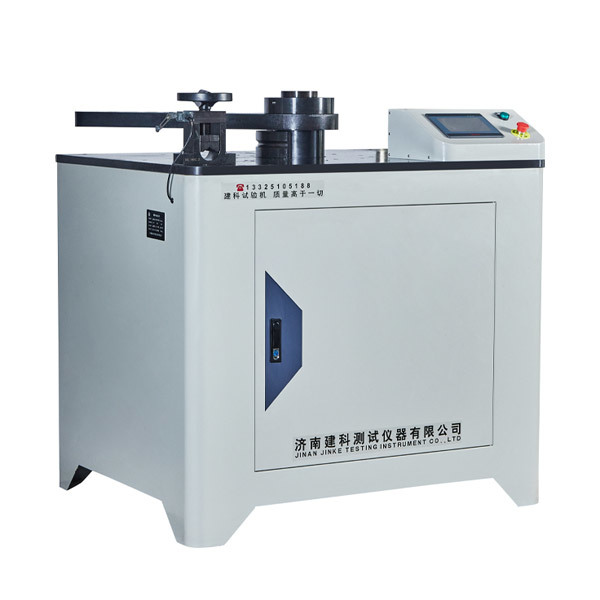

GGW-60A Steel Pipe Bending Testing Machine

Classification :

PRODUCT DETAILS

Perform forward and plane reverse bending tests on various types of steel bars, and can also be used for bending tests of metal plates.

Standards Compliance:

GB/T 244 Bending Test Methods for Metallic Material Tubes

GB/T 3091 Welded Steel Pipes for Low Pressure Liquid Delivery

GB/T 32976 Transverse Bending Test for Metallic Material Tubes

GB/T 28897 Steel-plastic Composite Pipes

GB/T 32958 Stainless Steel Composite Pipes for Fluid Conveyance

GB/T 32970 Longitudinal Submerged Arc Welded Steel Pipes for High Temperature and High Pressure Pipelines

GB/T 8163 Seamless Steel Pipes for Fluid Conveyance

GB/T 13793 Electric Resistance Welded Steel Pipes

CJ/T 120 Water Supply Coated Composite Steel Pipes

GB/T 8162 Seamless Steel Pipes for Structural Purposes

Product Features

Equipment structure: All-in-one machine with compact structure and small footprint;

Control mode: Fully automatic with Chinese touch screen, easy to operate;

Bending form: Bending tests are realized through forward and reverse rotation of the motor;

Bending angle: Forward and reverse bending angles can be arbitrarily set within 90º;

Safety protection: Safety shield as standard;

Product Parameters:

| Serial Number | Item | Parameter |

| 1 | Maximum diameter of bending steel pipe | Φ60.3mm |

| 2 | Forward bending angle | Arbitrarily set within 0 ~90° |

| 3 | Reverse bending angle | Arbitrarily set within 0~90° |

| 4 | Working disc rotation speed | ≤0.4rad/s |

| 5 | Machine dimensions | 1200×1500×1400mm |

| 6 | Machine weight | ≈1800Kg |

| 7 | Motor power | 1.5kW |

| 8 | Power supply | 380V |

Product Configuration (Subject to final order):

| Serial Number | Name | Model | Quantity |

| 1 | Main machine | 1 set | |

| 2 | Working shaft | 1 piece | |

| 3 | Random tools | Hexagon socket wrenches (5#, 10#, 12# each 1 piece) | 1 set |

| 4 | Bending core sleeves | 6× bending cores: Φ21.3×6, Φ26.7×6, Φ33.4×6 Φ42.2×6, Φ48.3×6, Φ60.3×6 8× bending cores: Φ21.3×8, Φ26.7×8, Φ33.4×8 Φ42.2×8, Φ48.3×8, Φ60.3×8 |

1 piece each |

| 5 | Rotating sleeves (including fastening screws) | Φ21.3, Φ26.7, Φ33.4, Φ42.2, Φ48.3, Φ60.3 | 1 piece each |

| 6 | Pipe clamping seats | Φ21.3, Φ26.7, Φ33.4, Φ42.2, Φ48.3, Φ60.3 | 1 piece each |

| 7 | Equipment files | Instruction manual, certificate of conformity, packing list | 1 copy |

APPLICATION FIELD

Aerospace

Automobile Manufacturing

Mechanical Manufacturing

Electronic Components

Textile Industry

Wires and Cables

CERTIFICATES

Computer Software Copyright Registration Certificate Electro-hydraulic Servo Universal Testing Machine Measurement and Control System V1.0

Computer Software Copyright Registration Certificate Electronic Universal Testing Machine Embedded System V1.0

Computer Software Copyright Registration Certificate Constant Temperature and Humidity System Control Software V1.0

Computer Software Copyright Registration Certificate for Interactive Universal Testing Machine Measurement and Control System V1.0

Computer software copyright registration certificate Pressure testing machine embedded system V1.0

Invention Patent Certificate Building Material Density Testing Machine

Utility Model Patent Certificate A deformation measuring device

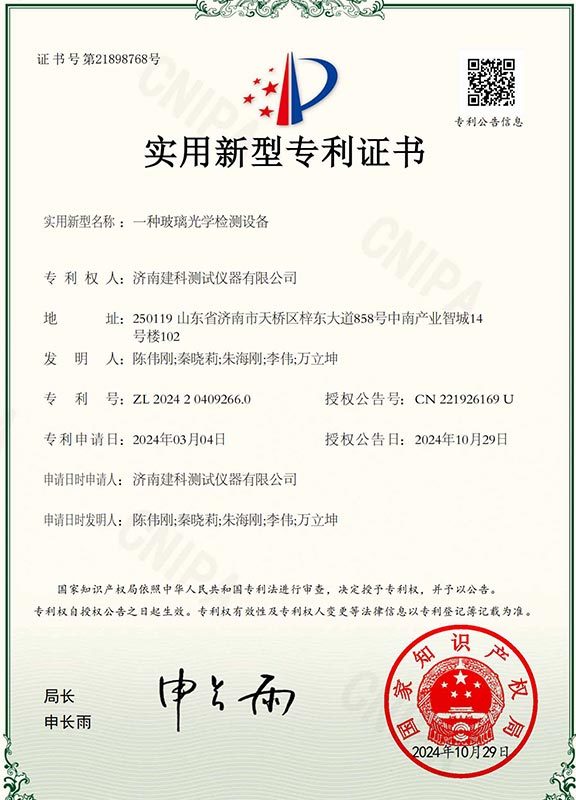

Utility Model Patent Certificate A Glass Optical Inspection Equipment

FAQ

Q:Does the product have quality inspection before loading?

Q:Can l go to your factory to visit?

Q:How many countries you already exported to?

Q:How long does your delivery time take?

Q:What product information do l need to provide?

Q:Can you send samples?

RELATED PRODUCTS

GET A FREE QUOTE