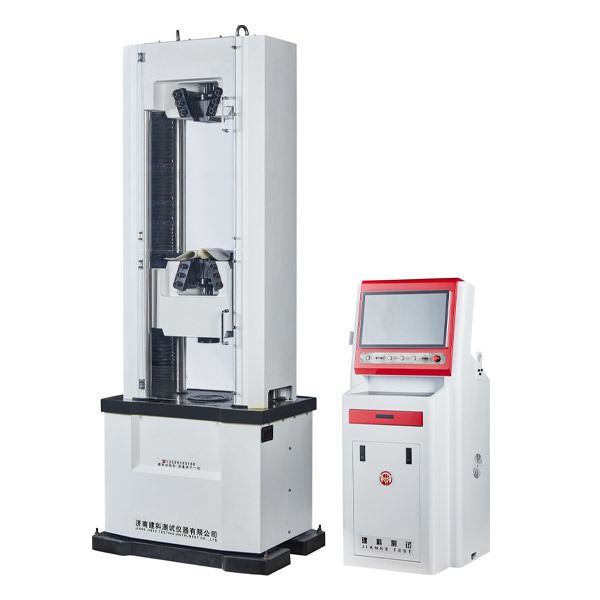

GWA-D Series Electro-Hydraulic Servo Steel Strand Testing Machine

Classification :

PRODUCT DETAILS

This testing machine is mainly used for tensile, compression, bending, shear and other tests on metal materials. It can be used for tensile, compression, bending, shear and flexural tests on other types of specimens when equipped with corresponding fixtures.

Based on standards:

ISO 6362-2;ISO 6892-2;ASTM E21-05;ASTM E8M-08;ASTM E9-89a(2000);BS EN10002-5;BS EN10002-1

Product features:

Complete machine Structure: The main engine, servo oil source, and measurement and control computer are designed as separate components.

Measurement and Control System: Consists of an oil tank, servo oil pump, control valve assembly, sensors, servo controller, control software, and a computer, ensuring high control accuracy and reliability.

Servo Oil Pump: Consists of a servo motor and high-pressure oil pump, offering fast response, a wide speed adjustment range, and low noise.

Servo Oil Pump: Consists of a servo motor and high-pressure oil pump, ensuring fast response, a wide speed adjustment range, and low noise. Spatial Adjustment: Raising and lowering are achieved through the motor's forward and reverse rotation using trapezoidal screws on both sides, resulting in a simple structure. Beam Structure: A semi-enclosed beam structure significantly enhances rigidity. Test Accuracy: The mainframe components are machined using a precision machining center. A servo-hydraulic control system distributes flow, and a high-precision spoke-type sensor measures force, ensuring a 0. Level 5 testing accuracy, exceeding national standards. Noise: Utilizes a brand-name ultra-quiet oil pump and servo motor control, resulting in virtually silent operation and an enhanced user experience. Specimen Clamping: Hydraulic clamping for ease of operation. Safety Protection: High-toughness protective netting is installed in the tension and compression areas, ensuring both safety and aesthetics.

Equipment Maintenance: The open crossbeam jaw base allows for easy maintenance and operation. An oil drain port is located at the bottom of the equipment for easy replacement of hydraulic oil.

Product Specifications:

| Model | GWA-600D | GWA-1000D |

| Maximum Load (KN) | 600 | 1000 |

| Effective range | 1%-100% F·S (full range, no steps) | |

| Testing machine accuracy | 0.5 level | |

| Number of columns | 4 columns + 2 lead screws | |

| Total motor power | 2.9kW | |

| Relative error of indication | ±1% | |

| Lower jaw lifting speed (mm/min) | 320 | |

| Maximum stretching distance (mm) | 1050mm | 1100mm |

| Maximum flat specimen gripping width (mm) | 80mm | 90mm |

| Flat specimen gripping thickness (mm) | 0-20mm | 0-40mm |

| Circular specimen gripping diameter (mm) | 13-40mm | 14-45mm |

| Maximum distance between bending supports (mm) | 300mm | 300mm |

| Maximum cylinder piston stroke (mm) | 200mm | 200mm |

| Effective space between two supports (mm) | 420mm | 465 |

| Control cabinet (length * width * height) (mm) | 650*600*1500mm | |

| Control cabinet weight (kg) | 300 | |

| Main Unit (Length * Width * Height) (mm) | 900*660*2050 | 970*700*2200 |

| Net Weight (kg) | 1750 | 2250 |

Product Configuration (Subject to final order):

| Name | Content | Remarks |

| Host | Includes protective net, spoke-type sensor, and displacement sensor | 1 unit |

| Servo control oil source | Includes embedded industrial computer | 1 unit |

| Electronic extensometer | YYU-500 | 1 unit |

| Round jaws | 2 pairs | |

| Flat jaws | 1 pair | |

| Pressure plate | 1 set | |

| Technical data | Instruction manual, packing list, certificate of conformity | 1 set |

| Testing machine software | Pre-installed on computer | 1 set |

APPLICATION FIELD

Aerospace

Automobile Manufacturing

Mechanical Manufacturing

Electronic Components

Textile Industry

Wires and Cables

CERTIFICATES

Software Registration No.11208041

Pressure Testing Machine Embedded System V1.0

Soft Registration No.11208039

Constant Temperature and HumiditySystem Control Software V1.0

A Kind of Door andWindow Performance Testing Equipment

A Concrete lmpermeability Test Device

A Temperature and Humidity Control Device

A Hydraulic Universal Testing Machine

FAQ

Q:Does the product have quality inspection before loading?

Q:Can l go to your factory to visit?

Q:How many countries you already exported to?

Q:How long does your delivery time take?

Q:What product information do l need to provide?

Q: Can we get the some samples? Any charges?

RELATED PRODUCTS

GET A FREE QUOTE