ZCNZ-W100Nm Series Microcomputer Controlled Torsion Testing Machine

Classification :

PRODUCT DETAILS

Testing Machine Introduction:

This machine is primarily used for testing the torsional mechanical properties of metal materials and specimens such as bolts, tools, finished products, structural components, drive shafts, parts, and fasteners at room temperature or under special conditions. It can also be used for torsional failure testing of non-metallic materials and finished products. The specimens are mounted between adjustable fixtures, adapting to different torsional mechanical properties tests.

Based on standards:JB/T 9370-2015 "Technical Specification for Torsion Testing Machines," GB/T 10128 "Room Temperature Torsion Test Method for Metallic Materials," JJG 269 "Verification Procedure for Torsion Testing Machines," etc.

Application Industries: Metrology and Quality Inspection, Metallurgy and Steel, Machinery Manufacturing, Fasteners, Hardware Tools, Automotive Parts, Universities, Research Laboratories, etc.

Engine Structure and Electrical System Introduction:

The mainframe utilizes a horizontal steel plate structure, which is formed in one step to ensure high overall rigidity. The test space is adjustable. The torque disc is connected to a sensor for torque collection, while the other end is for torque loading. A precision CNC servo motor, driven through a cycloidal reducer, drives the force disc to rotate, applying torque to the specimen. The torque collection end can be moved along a linear guide to adjust the test space and clamp the specimen. An environmental test chamber can be installed if necessary.

Transmission System:

A precision CNC motor, driven through a precision reducer, drives the force disc to rotate, applying uniform torque to the specimen, ensuring continuous speed adjustment and uniform loading over a wide range during the test.

Torque and Torsion Angle Measurement:

A high-precision torque sensor is used to measure torque in both positive and negative directions. The torsion angle is directly connected to the specimen area, avoiding the errors associated with motor angle encoders used by some manufacturers and ensuring accurate and reliable angle display. The collected sensor signals are processed by a computer data acquisition and processing system and displayed in real time on the computer screen.

Measurement and Control System:

The entire test process utilizes Windows-based, graphically interfaced software. The software simultaneously displays curves of the tested specimen's torque versus time, torque angle versus time, torque versus torque angle, and torque versus rotational angle. Parameters such as torsion angle, torque value, and peak torque are displayed in real time. Test results can be generated in Word or CXCEL report formats for convenient storage, printing, and analysis.

Test Procedure:

Select an appropriate specimen and adjust the test space according to the specimen length. Place the specimen on the workbench, insert one end into the clamping block with the corresponding clamp. Slowly push the movable base to slowly feed the specimen into the clamping block at the other end. Tighten the clamping block with the Allen wrench to confirm that the specimen is installed. Finally, perform the corresponding mechanical test using the torsional mechanical measurement and control software.

Protection Measures:

The entire device has overcurrent and overvoltage protection;

The control software has overload protection (over-range) and circuit breaker shutdown.

Protective devices can be installed according to the sample (optional)

Main technical performance indicators:

Optional sensor maximum range (Nm): 100, 50

Torque measurement range: 1%-100% FS

Minimum torque reading (Nm): 0.01

Test torque resolution 1/300000

Relative error of torque indication:≤±1.0% (Forward and reverse directions) Torque Repeatability Relative Error: <1.0% (Forward and reverse directions) Angular Measurement Range 0-10000° Relative error of rotation angle indication: ±1% (forward and reverse directions) Torsion angle (small angle measurement) Minimum display resolution: 0.01°pan>

Minimum angle reading: 0.01°

Test speed: 0.05-720°/min (2 rpm), customizable

Relative error of torsional speed indication: ±1% (Forward and reverse directions)

Torsion speed indication repeatability error: 1.0%

Distance between force plate and torque plate (mm): 0-450 Specimen clamping diameter: Customized according to actual specimen size Power supply: AC 220V ±10%, 50Hz;

Testing machine dimensions and weight:

Specimen gripping method: Standard flange chuck (customizable based on actual specimen) or three-jaw chuck

Test Level: Level 1

Testing Machine Operating Environment Requirements:

Within room temperature range of 10°C to 35°C; for tests requiring strict temperature control, the test temperature should be 23°C ± 5°

Relative humidity should not exceed 80%;

Properly install on a stable foundation; an>

In a clean environment free from vibration, corrosive media, and strong electromagnetic interference;

The power supply voltage fluctuation range should not exceed 10% of the rated voltage.

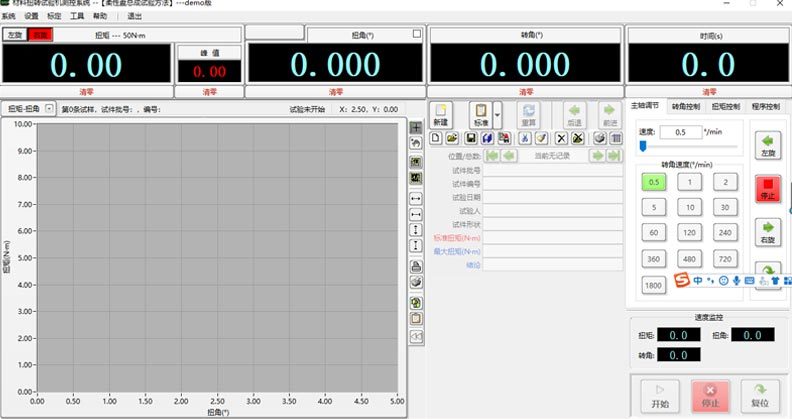

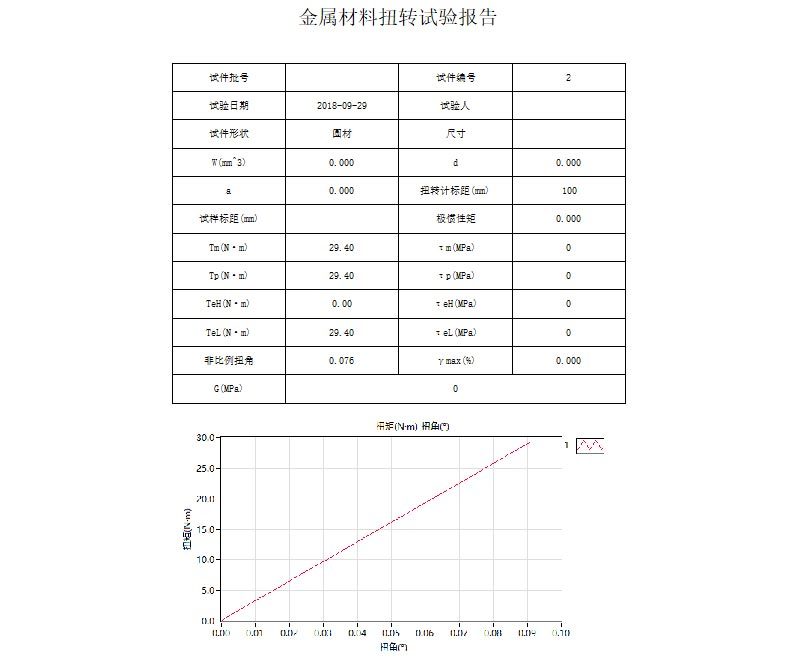

Software Interface Introduction:

Test Software Screenshot (Conventional): Data Display Area, Curve Display Area, Control Area

Sample Standard Generation, Test Result Output Type Selection

Edit, generate, and output reports (Word and Excel formats)

General Function Overview:

This software consists of modules for dynamic communication, speed control, parameter input, data processing, result observation, record query, chart display, chart printing, and data storage.

Diverse testing methods are available. You can set the material's torque and test its torsion angle; you can also set the material's torsion angle and test the torque, automating the entire testing process.

Can test the test piece's torque, maximum torque, yield point torque, upper and lower yield point torques, torsional strength, and shear modulus. Torque and torsion angle are automatically tracked and displayed.Test curve, torque value, torsion angle, and torsion speed. After the test, the test data is automatically processed, and performance parameters such as the material's yield point and torsional strength can be automatically calculated. Report formats can be customized according to user requirements and printed.

Specific functions are as follows:

Automatic zeroing: Test torque and angle can be reset to zero at any time as needed;

Automatic Shift: Automatically switches to the appropriate range to ensure load measurement accuracy;

Automatic Calibration: Automatically calibrates the test force indication for accuracy;

The collected signals are automatically processed, displayed in real time, and stored. Upon completion of the test, the system automatically returns to the initial test state.

Failure determination: Automatically returns to the initial test state after the specimen breaks.

Synchronize all data, indicators, and curves during the test.

Set the test torque (Tau) to test the torsional angle (omega) of the material/component. Set the torsional angle (omega) to test the test torque (Tau) of the material/component.

Automatically determine if a sample is acceptable by setting upper and lower limits. Multiple test points can be set (including forward and reverse detection).

Deflection caused by the sensor can be compensated. This means that deformation caused by the sensor and overall machine stiffness does not affect angle accuracy.

Equipped with automatic overload shutdown, overcurrent, and overvoltage protection.

User Preparation Requirements:

Responsible for product receipt, installation, and disassembly;

Specify sample testing Standards, specimen preparation, test methods, etc.;

Required site, environment, and power supply for equipment installation; Identify users and ensure dedicated equipment;

Carefully read the manual, operating procedures, and videos to learn how to use the equipment and perform simple troubleshooting;

Contact the manufacturer's after-sales service immediately if you have any questions.

Quality Assurance and After-Sales Service:

The equipment has a one-year warranty. During the warranty period, the supplier will promptly and free of charge repair service for all types of equipment failures. All types of damage not caused by human error will be promptly and free of charge. Sensors are not covered by this warranty. If the equipment malfunctions during use outside the warranty period, the manufacturer will provide on-site service or return the machine to the factory, depending on the nature of the malfunction, and will actively assist the ordering party in completing the repair task.

Product Configuration (Subject to final order):

| Serial Number | Name | Quantity |

|---|---|---|

| 1 | Torsion testing machine main unit (including dustproof pad) high-strength thickened steel plate | 1 unit |

| 2 | Testing machine chuck: flange chuck (customized according to specimen) or three-jaw chuck | 1 set |

| 3 | High-precision linear guide and slide (Taiwan Hiwin brand) | 1 set |

| 4 | …50Nm High-Precision Bidirectional Torque Sensor | 1 unit |

| 10 | Commercial Computer: Lenovo Desktop | 1 |

| 11 | Printer: Color Inkjet Printer | 1 |

| 12 | Information Acquisition Card or Acquisition Control Box, Testing Machine Control Software | 1 set |

| 13 | Technical Data (Instruction Manual, Certificate of Conformity, Packing List) | 1 copy each |

| 14 | Power cord, data cable, wrench, and other tools | 1 set |

APPLICATION FIELD

Aerospace

Automobile Manufacturing

Mechanical Manufacturing

Electronic Components

Textile Industry

Wires and Cables

CERTIFICATES

Software Registration No.11208041

Pressure Testing Machine Embedded System V1.0

Soft Registration No.11208039

Constant Temperature and HumiditySystem Control Software V1.0

A Kind of Door andWindow Performance Testing Equipment

A Concrete lmpermeability Test Device

A Temperature and Humidity Control Device

A Hydraulic Universal Testing Machine

FAQ

Q:Does the product have quality inspection before loading?

Q:Can l go to your factory to visit?

Q:How many countries you already exported to?

Q:How long does your delivery time take?

Q:What product information do l need to provide?

Q: Can we get the some samples? Any charges?

RELATED PRODUCTS

GET A FREE QUOTE